Address

41/551, Ground, A-5, Olavakkode Industrial Estate, Pudupariyarai, Palakkad – 678731, Kerala

Address

41/551, Ground, A-5, Olavakkode Industrial Estate, Pudupariyarai, Palakkad – 678731, Kerala

Manufacturers of L.T switchgear products such as switch fuses, changeover switches, porcelain fuse units, MCB distribution boards, phase selector distribution boards, energy meter boxes, automatic water level control switches, modular changeovers and isolators.

Company Profile

The electrical switchgear and control gear industry in India is fully developed and capable of producing a wide range of products needed by the power sector. According to IEMA, the growth percentage of LV switchgear was 6.1% in FY 23, grew to 13.7% in FY 24, and is expected to reach 14.8% in FY 25. Even though the industry posted negative growth in the last two fiscal years from FY 21, it has now revived smoothly, achieving double-digit growth of 14.8%. Hence, it is in a bright phase for manufacturing LT switchgear items such as switch fuses, fuse switches, fuse units, MCB distribution boards, and other allied products.

MENCO SWITCHGEAR PRIVATE LIMITED, Palakkad, is known for satisfactorily catering to the demands of customers. The company came into existence two decades ago and carries a history of more than six decades under the MENCO name in and around the southern states as a trusted brand. It was founded by the eminent industrialist Late Sri M.C. Menon in the early 1960s. Since then, MENCO has been recognized in the field for delivering quality products and has achieved market acceptance in the very first year under the brand name MPL, a registered trademark. The initial program to produce 96,000 units with a face value of ten million was achieved in five years, and now the company has geared up to boost production by adding new products. Recently, we have added a range of automatic switches, particularly water level control switches, timer switches, and float switches, and we continue to manufacture automatic changeover switches as part of our product range.

The Machine Shop is equipped with all machinery for in-house production of enclosures and brass and copper components Such as mechanical and hydraulic presses up to 150t capacity, drilling and tapping machines with 12 mm to 30 mm capacity, centre lathes of 1200 mm and 1500 mm capacity, turret lathe, bench grinders, hydraulic hacksaw, etc.

The Fabrication Shop consists of a guillotine shear with 1280×3 mm capacity, spot welding machine, arc welding machine, gas welding, bending machine, etc., for the fabrication of enclosures, panel boards, and pressed parts required for our products.The Tool Room consists of milling machines, surface grinders, centreless grinders, in addition to hand tools for cutting, grinding, etc., and all precision measuring equipment. We are also equipped with a smithy shop and a tempering furnace.

The Painting & Powder Coating Plant is capable of coating 1000 SFT per day with a 7-tank cleaning process and oven curing for both powder coating and painting processes. A small-capacity electroplating plant is also available for electroplating works.

Our Product range consists of :-

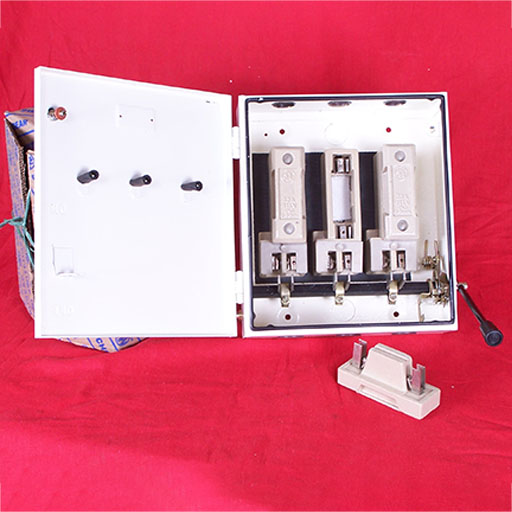

In sheet steel enclosure, Powder Coated Weather proof in Double Pole & Triple pole Conforms to IS: 13947 (part-3)1993 AC22-A

In current ratings of 16A to 100 Amps Conforms to IS:2086:1993 and additional Range of 200A & 300A as per KSEB design

In sheet steel enclosure Powder coated Fitted with selector switch, Indicator lamps MCB/Isolator provision in 40A/63A-4/6 way

In sheet steel enclosure Powder. coated, weather proof, in Double pole, Triple pole and Four pole.

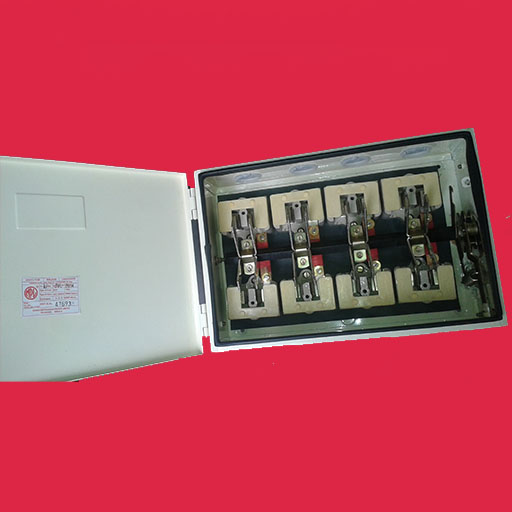

In sheet Steel enclosure Powder coated Conforms to IS:13032:1993 ranges of SPN & TPN Double door

In sheet steel Enclosure Powder coated for single phase and three phase with provision for fixing fuses

Our commitment is to produce quality products efficiently. Quality is one of the four key objectives in operations management along with cost, flexibility and delivery of good services and have proven this by the customer’s perception of our products. As quality is termed as continuous improvement by an eminent quality guru, we are also going ahead with total quality system by forming quality circles with the participation of shop workers and providing training on quality to improve the quality assurance.

We have received the ISO 9001:2008 certification during June 2014 itself and follow the stringent procedures as per the Quality assurance systems.